-

Four problems must be paid attention to in industrial pump selection2017-02-23

Four problems must be paid attention to in industrial pump selection2017-02-23The corrosion problem of industrial pump

Below for some commonly used chemical medium to talk about the selection of points:

1 sulfuric acid as one of the strong corrosive medium, sulfuric acid is the use of a very wide range of important industrial raw materials. Sulfuric acid concentration and temperature on Corrosion of materials in large difference, more than 80% concentration, temperature less than 80 DEG C concentrated sulfuric acid, carbon steel and cast iron has good corrosion resistance, but it is not suitable for high-speed flow of sulfuric acid, does not apply as pump material; ordinary stainless steel such as 304 (0Cr18Ni9), 316 (0Cr18Ni12Mo2Ti) of sulfuric acid is of limited use. Delivery of sulfuric acid pump valve is usually made of high silicon cast iron (casting and machining difficult), high alloy stainless steel (alloy 20) manufacturing. Fluorine plastic has good resistance to sulfuric acid, using fluorine pump (F46) is a more economical choice. The company applies to products: IHF fluorine pump, PF (FS) strong corrosion resistant centrifugal pump, CQB-F fluorine plastic magnetic pump, etc..

The majority of 2 hydrochloric acid metal material are not resistant to hydrochloric acid corrosion (including stainless steel), molybdenum containing high silicon iron also can only be used for 50 DEG C, 30% hydrochloric acid. And metal materials, the vast majority of non-metallic materials have good corrosion resistance to hydrochloric acid, lined rubber pump and plastic pumps (such as polypropylene, fluorine plastic, etc.) is the best choice for hydrochloric acid transport. The company applies to products: IHF fluorine pump, PF (FS) strong corrosion resistant centrifugal pump, CQ polypropylene magnetic pump (or fluorine plastic magnetic pump), etc..

3 most of the general metal nitrate nitric acid was rapid corrosion, stainless steel is the most widely used nitric acid resistant materials, has good corrosion resistance to temperature all concentrations of nitric acid, worth mentioning is the stainless steel containing molybdenum (316, 316L) on the nitric acid corrosion resistance is not better than ordinary stainless steel (304, 321),. The high temperature nitric acid, usually titanium and titanium alloy materials. Company's products are: DFL (W) H chemical pump, DFL (W) PH shielding chemical pump, DFCZ flow pump, DFLZP self-priming pump, IH chemical pump, CQB magnetic pump, etc., 304.

4 acetic acid is one of the most corrosive substances in organic acids

Severe corrosion, stainless steel is an excellent acid resistant material, containing molybdenum 316 stainless steel can also be applied to high temperature and dilute acetic acid vapor. High temperature and high concentration of acetic acid or other corrosive media and other harsh requirements, can choose high alloy stainless steel or fluorine plastic pump.

5 alkali (sodium hydroxide) iron and steel widely used in the temperature of 80 degrees Celsius, the concentration of sodium hydroxide solution, there are many factories in the temperature of 100 DEG C, less than 75% of the ordinary steel, corrosion, but the economy is good. The alkali corrosion resistance of ordinary stainless steel and cast iron had no obvious advantages, medium to allow incorporation of a small amount of iron stainless steel is not recommended. The use of high temperature alkali titanium and titanium alloy of high alloy stainless steel. The company generally cast iron pumps can be used for low concentration of alkali at room temperature, special requirements can be used all kinds of stainless steel pumps or fluorine plastic pump.

6 ammonia (ammonium hydroxide) most of the metal and nonmetal liquid ammonia and ammonia (ammonium hydroxide) in the corrosion is very slight, copper and copper alloy should not be used. Most of the products are suitable for ammonia and ammonia.

7 salt water (sea water) ordinary steel Sodium Chloride Solution and sea water, salt water corrosion rate is not high, are generally required to use paint protection; all kinds of stainless steel has a very low corrosion rate, but may be due to localized corrosion caused by chloride ions, typically 316 stainless steel is better. Various types of chemical pumps have 316 material configuration.

8 alcohols, ketones, esters, ethers common alcohols media are methanol, ethanol, ethylene glycol, alcohol, ketones medium with acetone and butanone, a variety of media methyl esters, ethyl ester, ether medium with ether, ethyl ether, butyl ether, etc., they are basically no corrosive materials can be used to apply. The specific use should also be medium properties and related requirements to make reasonable choices. In addition, the attention is paid to ketones, esters, ethers of a variety of rubber solubility, select the sealing material to avoid mistakes.

-

Vacuum pump oil after troubleshooting method2017-02-22

Vacuum pump oil after troubleshooting method2017-02-22Vacuum pump oil after troubleshooting method

1) pump outlet injection phenomenon

Too much oil to reduce the amount of oil added

Intake air for a long time should be avoided;

2) pump outlet fog phenomenon:

Check the air intake and other parts of the leak

3) low vacuum:

If the pump cavity and oil mixed with other light liquid, should be running for a period of time after the new oil

Check whether there is leakage of the seal parts of the pump

Check the instrument

4, oil diffusion pump, booster pump oil change notice:

Selection of good quality oil;

The oil shall pour out all the old oil;

The use of gasoline or special cleaning agent for cleaning all the parts inside the pump, and with acetone or diethyl ether dry, dried in the oven, hair dryer is also available;

The installation of pump and parts according to the original position, nozzle should be in the pump cavity in the middle

The operator should wear white gloves degreasing assembly, according to the requirements of the amount into the diffusion pump oil or oil booster pump;

5, the problems arising from the use of diffusion pumps and removal methods:

1) low vacuum:

Check vacuum;

Check whether the cooling water, water temperature is high;

Is there any blockage in the cooling water pipe;

Electric power is too large or too small;

Low supply voltage;

Incorrect assembly of nozzles;

Incorrect gauge control;

Abnormal instrument or wire;

Vacuum system leakage;

Long term use of residual coating is too thick;

2) caused by improper operation of the rapid oxidation of oil, that is red or black:

Check the job is to forget to open the cold water;

There is a serious leakage of vacuum system;

Diffusion pump in the atmosphere into the diffusion pump;

There is volatile gas or dust inside the pump chamber.

-

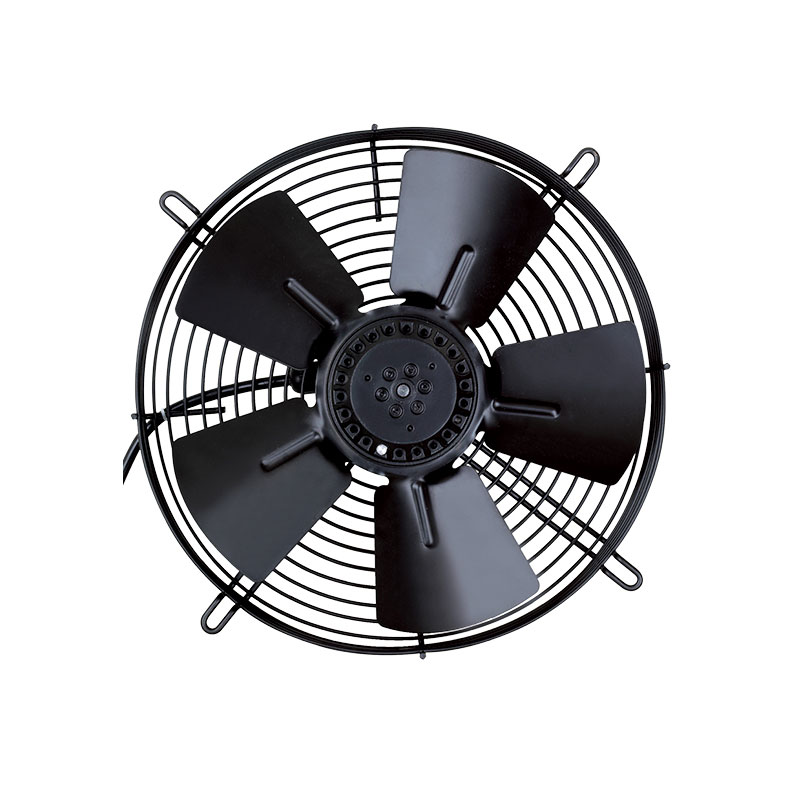

Overview of external rotor axial fan2017-02-22

Overview of external rotor axial fan2017-02-22(1) classification of external rotor axial fans

YWF series outer rotor axial fan is divided into two types: single phase asynchronous capacitor operation and three phase asynchronous operation. Single phase capacitor running motor is 120V, 60Hz or 220-240V, 50/60Hz, three-phase asynchronous motor is 380V, 50/60Hz. We can also produce according to customer requirements of different voltage, frequency motor.

According to the different diameter of fan impeller, there are thirteen types of external rotor axial flow fan from 200mm to 900mm. The number of blades has 5 pieces, 7 pieces of material with low carbon steel and plastic material, blade angle of a variety of wide range of options.

According to the different wind direction, the blower also has the blowing or suction. Suction wind by wind leaf to the net cover by wind direction; blowing wind direction of leaf net cover. In addition, according to the degree of concave convex of the outer rotor end line, the utility model can be used as a blowing or sucking wind, a concave suction wind, and a blowing device.

According to the different protection levels, can be divided into IP54, IP44 and fully open axial fan. IP54 axial flow fan, mainly used for equipment, refrigeration evaporator, air cooler, chiller and condensing unit; IP44 axial flow fan, mainly used in central air-conditioning, heat pump, heater, dehumidifier and air circulation etc.. Full open axial flow fan, mainly used for air purifiers and other clean environment, humidity is not on the ventilation equipment.

According to the different characteristics of the fan, can be divided into a net cover, without mesh cover two kinds of net cover with flat type, net cover with flat type, flat type, concave net type, wall flat net type and wall shaped concave net type, etc.. Installation way type, cylindrical circular frame, wind guiding panel (cylindrical), air duct type.

According to customer demand, we can produce single speed, double speed, three speed motor.

(two) product application

YWF external rotor axial fan has the advantages of compact structure, convenient installation, reliable operation, low noise, energy saving and high efficiency. The products are widely used in hotels, restaurants, factories, office buildings, theaters and other facilities, equipment or the refrigerator freezer as for ventilation and heat dissipation. (for example, with the supermarket freezer refrigerator, ice machine, cold machine, cold water machine, condensing unit and other refrigeration equipment or facilities, and dehumidifier, evaporator, wall fan, fire fan, central air-conditioning fan and other equipment for use).

At the same time, according to the different installation methods, there are different applications:

The air duct type: building facilities for indoor ventilation.

The wind guide panel type: for air cooler, evaporator, air conditioning, radiator, dehumidifiers and other occasions

Type: with the use of heaters, electric welding machine, low temperature box, air conditioning module machine, central air-conditioning outdoor unit and other ancillary equipment for ventilation, kitchen and toilet, bathing places, bars, hotels, opera and refrigeration and freezer supporting the use of.

-

Vacuum pump attention?2017-02-22

Vacuum pump attention?2017-02-22Select vacuum pump precautions:

1, vacuum pump vibration generated on the working process and the environment have no effect. If the process is not allowed, should choose no vibration of the pump or take anti vibration measures.

2, to understand the composition of the gas is pumped, the gas contains no condensable vapor, whether or not the particle dust, corrosion, etc.. When selecting a vacuum pump, it is necessary to know the composition of the gas. If the gas contains steam, particles, and corrosive gas, should be considered in the pump inlet pipe on the installation of auxiliary equipment, such as condensers, dust collector, etc..

3, the vacuum pump in its working pressure, should be able to exhaust the vacuum equipment in the process of generating all the gas.

4, the correct combination of vacuum pump. Because the vacuum pump has selective pumping, therefore, sometimes choose a pump can not meet the pumping requirements, the need for a combination of several pumps, complement each other to meet the pumping requirements

-

Small vacuum pump2017-02-21

Small vacuum pump2017-02-21A small vacuum pump is a vacuum pump, the working medium is mainly used for gas, need long-term idle, dry and so on occasions.

Definition

Small vacuum pump refers to the micro vacuum pump, because of the small size of the micro vacuum pump is usually referred to as a small vacuum pump. Micro vacuum pump (i.e. small vacuum pump) refers to a into a suction nozzle and an exhaust nozzle of each one, and can continue to form a vacuum or negative pressure in the inlet; the formation of micro positive pressure exhaust nozzle; the main working medium for gas, an instrument of small volume.

A sealed container (at the beginning of the internal pressure is 100KPa), the micro vacuum pump, continuous pumping on it, the gas pressure in the sealed container will be lower than the atmospheric pressure, reach the absolute pressure of 60KPa. Not only that, after special technical improvements, in addition to the micro vacuum pump single pumping, pumping pump can also form a micro vacuum pump dual-purpose (i.e. the exhaust end can produce relatively large positive pressure), for pressurization, air, and water resistance of the system and overcome the dual micro vacuum pump is very unique, it can the need for long-term idle, dry and so on occasions, unlike the general pump idling, or dry transfer will damage the pump.

Basic principle

The circular motion of the motor, the mechanical device makes the diaphragm inside the pump to do reciprocating motion, thus the pump cavity of fixed volume air compression, stretching to form a vacuum (negative pressure), the pump inlet and the outside atmospheric pressure difference, under the action of the pressure difference of gas pressure (suction) into the pump the cavity is then discharged from the exhaust port.

Selection criteria

First, we must clear the use of micro pump. We divided into three categories one by one.

First, if only by micro pump output of compressed air.

Simply speaking, it is only to cheer, inflatable air pump, the basic need. This situation is relatively simple, according to the output pressure from large to small optional: PCF5015N, FAA8006, FAA6003, FAA4002, FM2002, FM1001. Of course, we must refer to the relevant technical parameters such as traffic indicators.

Two, if the following circumstances, should choose PHW600B or WAA series products.

1, the use of micro pump pumping or vacuum, but sometimes there will be liquid water into the pump cavity.

2, the requirements of the micro pump can pump and pump.

3, the main use of micro pump pumping, but do not want to rely on artificial before pumping water". (some of the pump at work before the need to add some "artificial diversion", this pump to lower the water pumped, otherwise the pump can not be pumped or even damaged.) The advantage of the PHW600B or WAA series is that it does not come into contact with the water, it is evacuated, the formation of a vacuum after the pressure to the pressure up, and then start pumping.

4, with a micro pump pumping, but sometimes it is possible that the pump can not pump water, in the dry turn state. Some traditional pumps are afraid of "dry", even fatal. The PHW600B or WAA series of products is essentially a complex function of the pump, which integrates the functions of vacuum pumps and pumps, it was called "vacuum pumps". Therefore, in the absence of water, it will vacuum, when there is water pumping it. Whether it is pumping or pumping state, are part of the normal work, there is no so-called "dry" damage.

Three, if the use of micro pump pumping, the situation is slightly more complicated.

1, to determine the micro pump suction end condition

There are two types of micro pumps for pumping: gas sampling pumps and micro vacuum pumps. Although it is usually not easy to distinguish them simply referred to as a micro vacuum pump, but from the technical point of view there are two differences, more attention should be paid to selection.

In short, the gas pump can only take a small load (i.e. the pump suction can't end too much resistance, but the price is cheaper); micro vacuum pump in the strict sense can bring large load (pumping end allow large resistance, or even completely blocked), but the price is slightly expensive. The difference between the two can be seen in the article on the micro vacuum pump and the difference between the gas sampling pump, no longer repeat.

The gas sampling pump are: PM series (specific models such as: PM950.2, PM850.5, PM8001, PM7002, PM6503); micro vacuum pump: VM series, VAA series, PK series, PC series, VCA series, VCC series, VCH series, PH series, FM series, FAA series, PCF series, all of these specifications the series is a real miniature vacuum pump, such as VM7002, VAA6005, PC3025 etc..

For the size of the micro pump suction end of the instrument can be measured, and it is the technical parameters of the pump, the inlet allows maximum resistance Por value can be compared to know whether the selection is appropriate. Usually according to the experience of using simple methods, such as the following several cases belong to the high load (i.e. pump end gas resistance), only in the selection of micro vacuum pump range in the pump exhaust end to take long pipe, pipe bending, bending or more severe or even obstruction closed. Or the pipe hole is very small (e.g., less than 2 mm diameter); the throttle valve, solenoid valve, pneumatic switches, filters and other components in the pipeline; the pump outlet is connected with the sealed container, the container or is not closed but a smaller amount of the pump inlet; the air intake and the suction connection for adsorption of objects (such as precision integrated block, etc.); the pump suction end is connected with the filter container, the container port is placed for accelerating the filter, liquid filter.

2, to determine the micro pump exhaust end condition

These are discussed in the end of the micro pump suction resistance, according to these criteria have narrowed the scope of the selection, but also must consider the exhaust side resistance, so as to ultimately determine the optional range.

In practical application, the exhaust conditions facing micro vacuum pump is not the same: one is the exhaust smoothly through the atmosphere; the other is the exhaust resistance, such as in the exhaust pipe on the valve, elbow, small damping sensor, non dedicated muffler, on the surface of the liquid to gas exhaust and exhaust to closed or semi closed container etc.. In modern design and manufacture, the face of the different conditions of the vacuum pump vacuum treatment. "Exhaust port allows maximum resistance Por value" this parameter is the calibration of the pump exhaust capacity, so that we can use a rigorous technical means to determine the appropriateness of selection.

Simply, for system exhaust resistance is large, the scope of our selection is: FM series, FAA series, PCF series; system for small exhaust resistance, the selection scope is: VM series, VAA series, PK series, PC series, VCA series, VCC series, VCH series, PH series. According to the above steps, we have been able to determine the scope of the selection of micro pump. In the delineation of a number of optional series, and then based on our requirements for the flow and vacuum can determine the specific model. For poor quality products are not included in this article, try not to use. Pay attention to the choice of parameters to be left, especially the flow parameters. After the pump into the gas system, due to the pipeline, valves and other gas circuit components to cause pressure loss, will attenuate the flow, so the flow rate is less than the nominal flow rate of the pump.

Selection problems

There are some problems related to the selection of the following list, according to the use of consideration.

1, with load startup problem.

If the micro pump before starting the pumping port it has a vacuum or exhaust port already exists pressure to consider other technical parameters of the pump intake maximum starting load Pis value, the exhaust port maximum starting load Pos. Typical application examples is the use of micro pump to maintain the vacuum container or positive pressure, when the vacuum container or positive pressure below the set value, need to start the pump power is higher than the set value, stop. You can start in their own can achieve the ultimate vacuum of the products are: VM series, VAA series, PK series, PC series, VCA series, VCC series, VCH series, PH series; you can start at the maximum output pressure can reach itself under the products are: FM series, FAA series, PCF series. The performance requirements of the manufacturer's technical level is higher.

2, micro pump medium temperature problem.

According to the temperature of the gas through the pump, the choice of ordinary or high temperature.

3, the reliability of micro pump.

Depending on the severity of the consequences of the failure of the micro pump, according to their own requirements. High quality products, the average failure free running time is greater than 1000 hours, some up to thousands of hours. In particular, this parameter is determined in the running state of full load, uninterrupted under the worst conditions, if the actual usage is not full or continuous operation, the value will be higher, much as the pump working condition set. The performance is a test of the manufacturer's technical strength, can be seen from the appearance of some products, such as the use of special motor rather than ordinary low-cost motor, the volume of the case is relatively heavy weight. According to the price of the product can also get to know.

4, micro pump electromagnetic interference.

If there is a precision circuit to control the micro pump, depending on the anti-interference ability of the circuit may be required to order a small electromagnetic interference micro pump.

Application scope

Research, gas sampling, instrumentation, chemical analysis, health care, medical and health, bio engineering, automatic control, environmental protection, water treatment and other fields

0086-576-86275888

0086-576-86275888  0086-576-86259698

0086-576-86259698